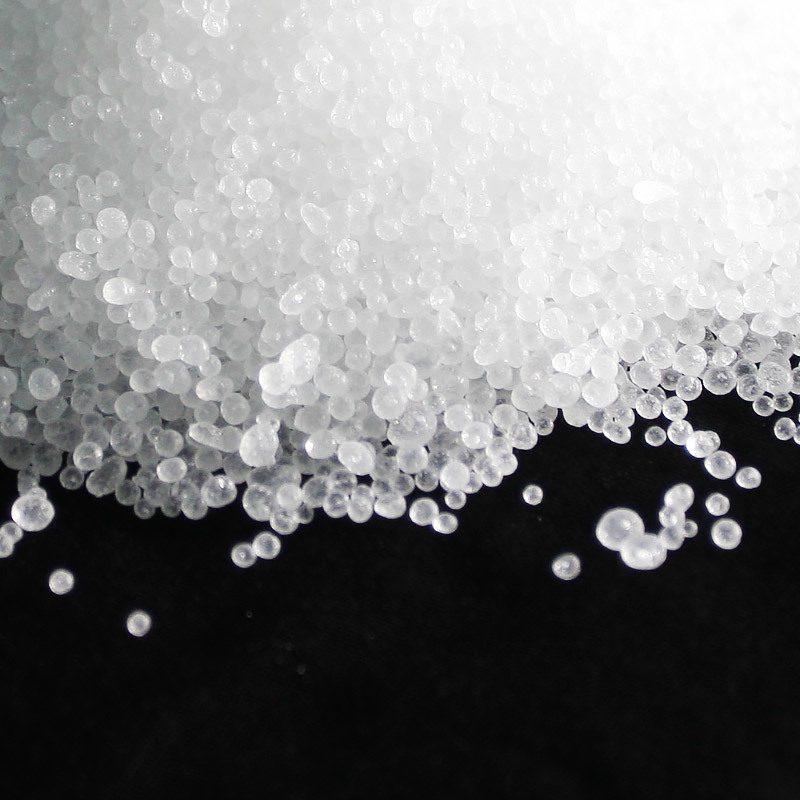

PE wax features

Release time:

2022-08-16

PE wax application scope of work: it can be widely used in enterprise production technology to manufacture masterbatch, granulation, plastic steel, PVC pipe, hot melt adhesive, rubber, shoe polish, leather brightener, cable system for analysis of insulation structure design materials, floor wax, plastic development industrial profiles, ink, injection molding and other products.

PE waxScope of application: It can be widely used in enterprise production technology to manufacture masterbatch, granulation, plastic steel, PVC pipe, hot melt adhesive, rubber, shoe polish, leather brightener, cable system for analysis of insulation structure design materials, floor wax, plastic development of industrial profiles, ink, injection molding and other products.

1. Main features: low viscosity, high softening point, good hardness, non-toxic, good thermal stability, low volatility at high temperature, good pigment dispersion, not only has excellent external lubricity, but also has strong internal lubricity. Improve the production efficiency of plastic processing, have good room temperature moisture resistance and excellent chemical resistance, improve the appearance of the finished product.

2.PE wax is soluble in polyethylene, polyvinyl chloride, polypropylene and other resins due to good external and internal lubricating properties. PE wax can be used as a lubricant for extrusion, calendering and injection molding products. It can effectively improve the processing technology efficiency of the enterprise, prevent and overcome the adhesion of film, tube and plate, improve the finish and gloss of the finished product, and improve the appearance of the company's finished product.

3.PE wax, as an enterprise, can conduct research on dispersants for information concentrated color masterbatch and lubricating systems for filling color masterbatch and degrading color masterbatch through different thermoplastic composite resins in various ways, which can improve the performance, surface working temperature gloss, lubricity and thermal stability of processing technology products such as PP and PVC.

4.PE wax is used as a lubricant for cable insulation materials, which can enhance the diffusion of fillers, increase the extrusion speed, increase the mold flow, and promote the release of the mold.

5.PE waxAs a domestic rubber processing aid, it can enhance the diffusion of fillers, increase the development speed of extrusion molding, increase the flow of mold design, and facilitate demoulding. Good light resistance and chemical properties, can be used as a pigment carrier, can improve the abrasion resistance of pigments and inks, improve the dispersion of pigments and fillers, prevent pigments from sinking to the bottom, and can be used as a homogenizer for paints and inks.

6. As a natural or synthetic softener and lubricant for fibers, it improves wear resistance, tear strength, wrinkle resistance and needle-free sewing, reduces needle cutting, and adjusts different touch. Can improve the production of paper gloss, durability, hardness and wear resistance, improve and paper water resistance and drug resistance related properties, improve the use of paper aesthetics.

7. Add paraffin wax in China to improve its performance. Excellent electrical insulation performance, adding insulating oil, paraffin or microcrystalline paraffin, so that its softening temperature, viscosity and insulation performance, can be used for cable insulation, capacitor and transformer winding moisture-proof coating. It can also be used in the production of Chinese leather shoes, oils, candles, crayons, cosmetics, leather additives, hot melt adhesives, etc.

PE waxWidely used in masterbatch, granulation, plastic steel, PVC pipe, hot melt adhesive, rubber, shoe polish, leather brightener, cable insulation materials, wax, plastic profiles, printing ink, injection molding and other products.

Key words:

PE wax

Previous article

Next article

Previous article

Next article

recommend reading